English

日本語

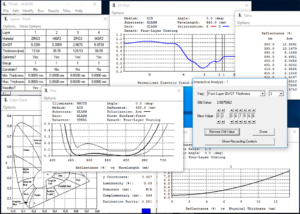

Software for the Design and Manufacture of Optical Thin Film Coatings

The industry’s leading software for designing and manufacturing optical thin film coatings that won’t require you to take a class or hire an expert to use. It’s simple, it’s easy, and with our product TFCalc, you can design coatings for lenses, computer monitors, eyeglasses, window panes, light bulbs, hot and cold mirrors, x-rays mirrors.

Why TFCalc?

Why is TFCalc used by so many? A brief answer:

- TFCalc is easy to use

- TFCalc is a stable, reliable tool that works on Windows

- TFCalc has the features that coating designers need

- TFCalc has features that other design programs do not have

- TFCalc allows the user to define an unlimited number materials, substrates, and illuminants

- TFCalc allows layers to have variable index, or to be a mixture of materials

- TFCalc has powerful optimization capabilities, such as

- needle optimization

- global search

- sensitivity optimization

- optimizing cone-angle targets

- TFCalc provides a cost-effective solution

More information about TFCalc

- Can maintain the symmetry of a design while it’s being optimized.

- Helps the designer locate the designs that minimize the merit function.

- Utilizes needle optimization, a powerful tool in designing multilayer coatings.

- Allows for needle/tunneling, so the designer has more designs from which to choose when it comes to manufacturing.

- Computes EFI (electrical field intensity) to calculate performance of thin film coatings.

- Utilizes Monte Carlo method to generate random designs…and then displays results!

- Can compute the sensitivity of each coating layer of a design.

- Can simulate the output of an optical monitor, used in the manufacturing thin film coatings.

- Determines the refractive index of a thin layer coating using variable materials and fitting a dispersion formula.

- All computations are done with 10-byte extended-precision numbers, which offer about four additional digits. This is important for designs having many layers.